1. Box-Shaped Cargo

1.1 Excessive Over-width Cargo (Heavy Cargo)

Cargo with a width exceeding 4.0 meters has a tipping point located relatively closer to the center, which significantly increases the risk of overturning when vessel rolling occurs.

This risk becomes even greater as the cargo weight increases.

Where the cargo does not have built-in lugs (lashing points) that allow for direct lashing, additional lashing arrangements are required, taking into account the cargo characteristics, in order to prevent movement during transport.

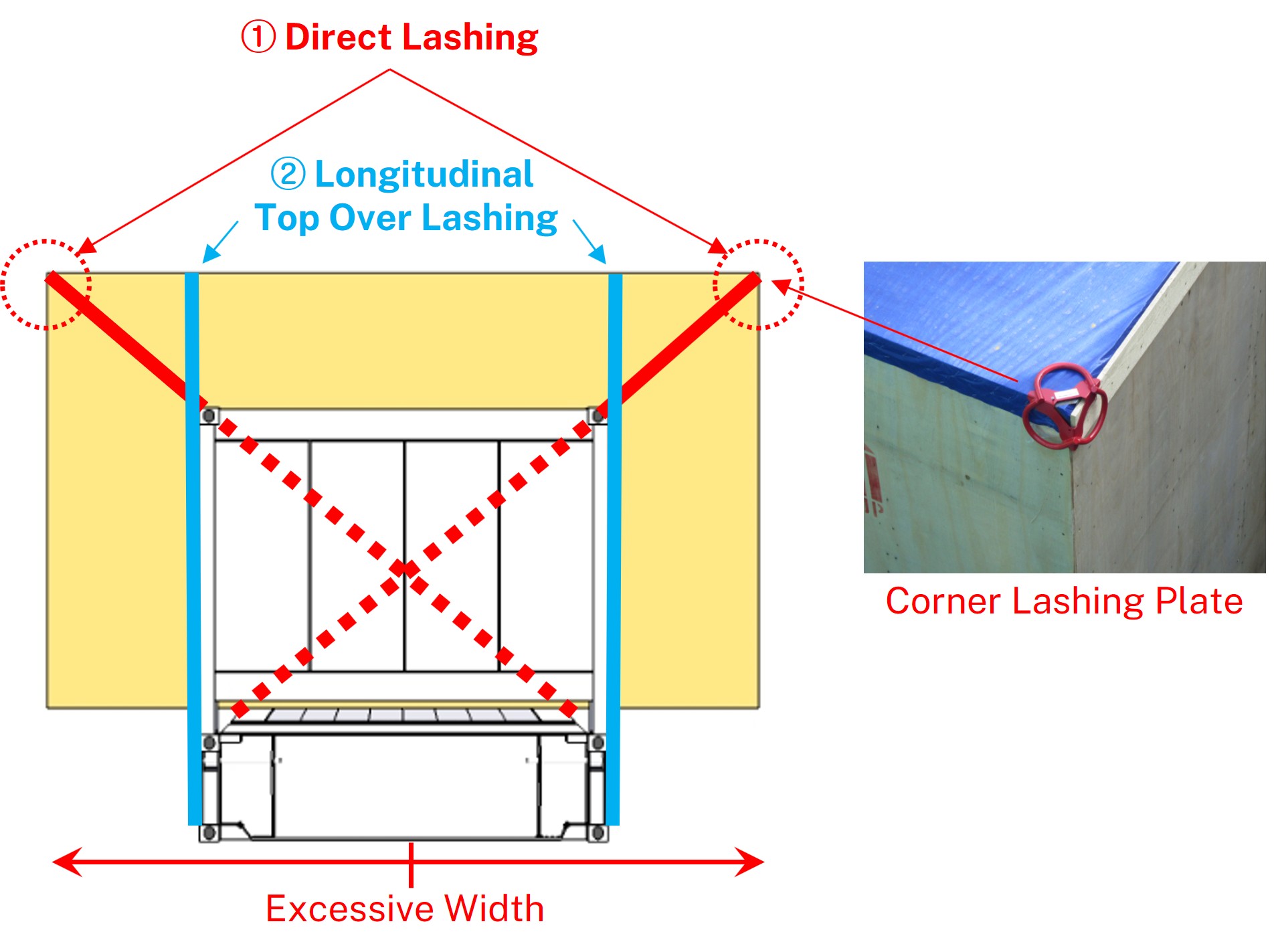

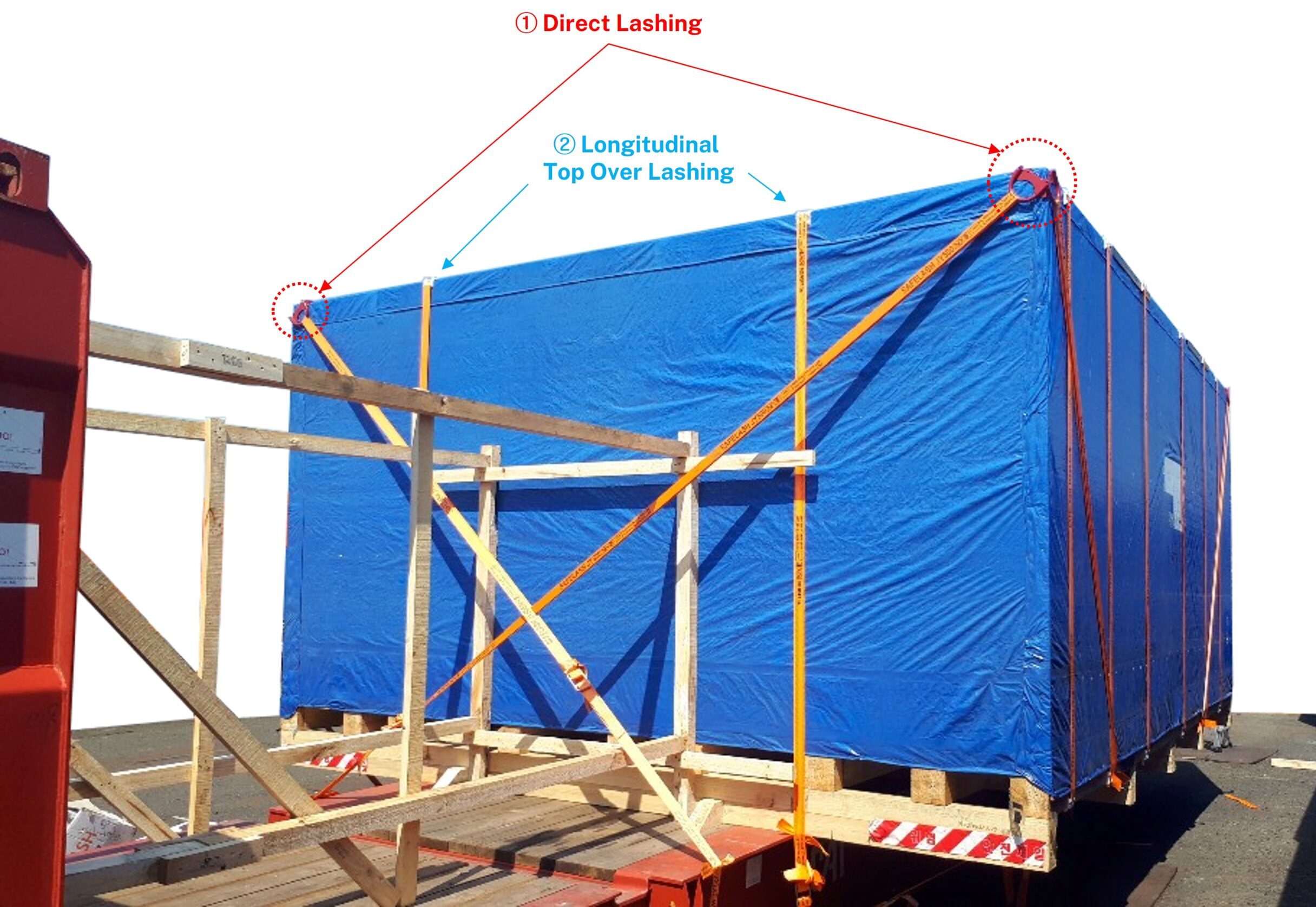

① Direct Lashing

- Lashing points shall be installed at the four upper corners of the box-shaped cargo, and direct lashings shall be applied diagonally to the flat rack lashing rings.

- This lashing method is effective in preventing sliding movements of the cargo in both the transverse (left–right) and longitudinal (fore–aft) directions.

② Longitudinal Top Over Lashing

- Top-over lashings shall be applied along the upper edges on both sides of the cargo in the fore-and-aft direction.

- This arrangement provides additional restraint against tipping caused by vessel rolling.

1.2 Excessive Over-width Cargo (Light Cargo)

Cargo with a width exceeding 4.0 meters also presents an increased risk of tipping due to its relatively inward tipping point when vessel rolling occurs, even when the cargo weight is relatively low.

Where direct lashing using built-in lugs is not possible, the following additional lashing measures shall be applied to prevent cargo movement during transport.

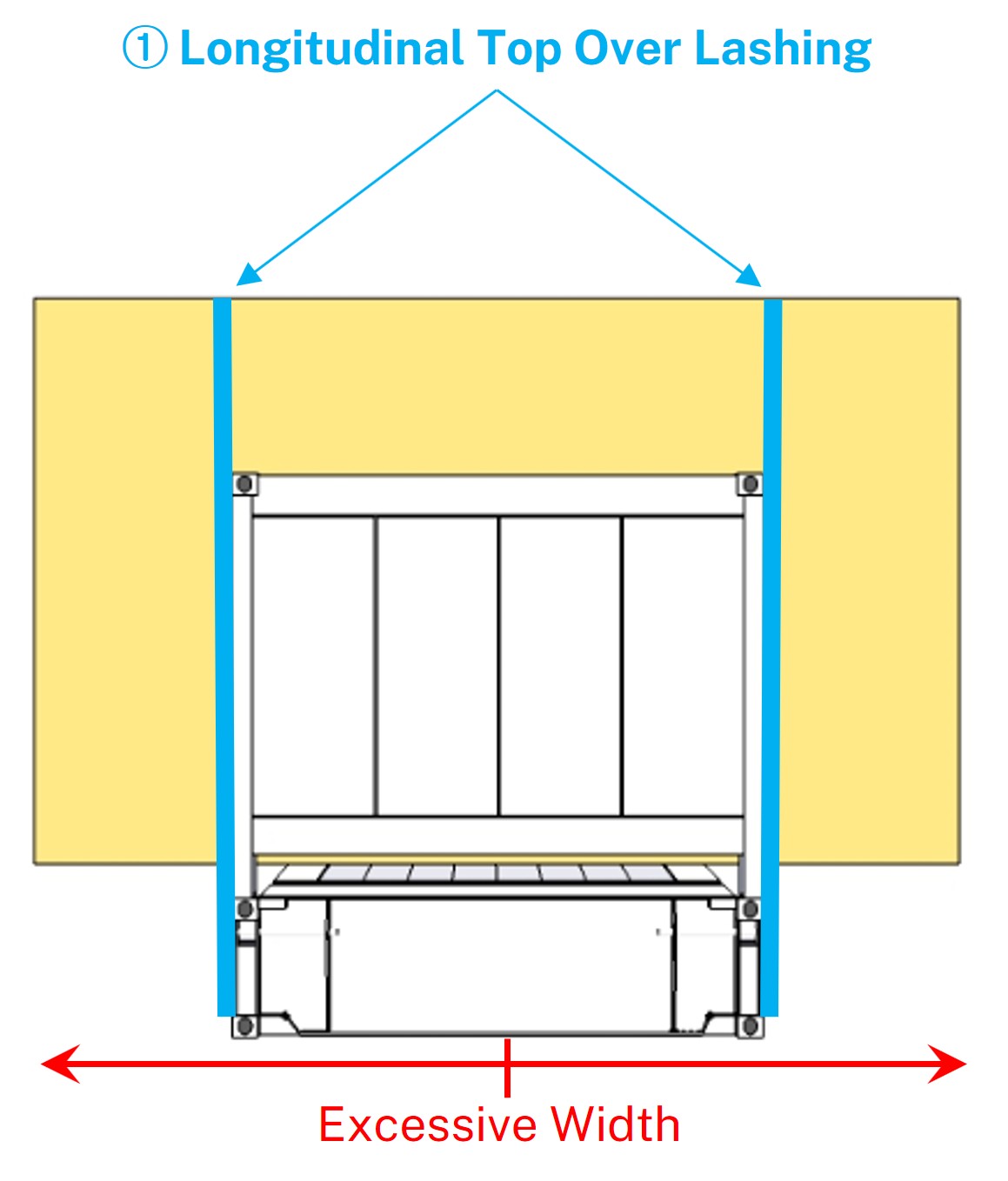

① Longitudinal Top Over Lashing

- Top over lashings shall be applied along the upper edges on both sides of the cargo in the fore-and-aft direction.

- This method is effective in preventing tipping caused by vessel rolling.

2. Round-Shaped Cargo

2.1 Cylindrical Cargo

From a lashing perspective, cylindrical cargo is classified as one of the most unstable cargo shapes.

Unlike box-shaped cargo, cylindrical cargo has no edges, which prevents lashings from positively engaging with the cargo geometry. As a result, lashing materials tend to slide easily along curved surfaces.

Even if the cargo appears to be properly secured immediately after stuffing, vessel vibration and rolling during the voyage can cause progressive displacement of the lashing position.

In other words, although the cargo may appear secured externally, it is often not effectively restrained in practice.

While conventional lashing systems are primarily designed to control sliding, cylindrical cargo requires control of sliding, rotation, and rolling simultaneously.

Therefore, cylindrical cargo must first be form-fitted using saddles, followed by the application of loop lashings, in order to achieve adequate securing stability.

① Saddle

- Because stable securing cannot be achieved by lashing alone, cylindrical cargo shall be supported by saddles installed beneath the cargo, incorporated into a cradle or skid, to physically prevent rolling.

- Saddles shall be manufactured with a curved contact surface (semi-circular or V-shaped) matching the cargo diameter and shall be installed at a minimum of two points in the fore-and-aft direction to prevent movement or rotation on the supports.

② Load Distribution (for Heavy Cargo)

- When saddles are installed at only two points, the load of heavy cargo may be concentrated locally, creating a risk of exceeding the allowable load of the container floor.

To mitigate this risk, a grillage arrangement in a lattice (井-shaped) configuration may be applied to distribute the load to the structurally reinforced bottom side rails of the flat rack. - Base layer:

Longitudinal dunnage is installed directly on the left and right bottom side rails to form the primary load-bearing points. Additional auxiliary dunnage is placed along the centerline to pass over the cross members. - Intermediate support:

Transverse dunnage is installed on top of the base timbers to form a “bridge” structure. - Top layer (Saddle):

Saddles are positioned on top of the transverse beams.

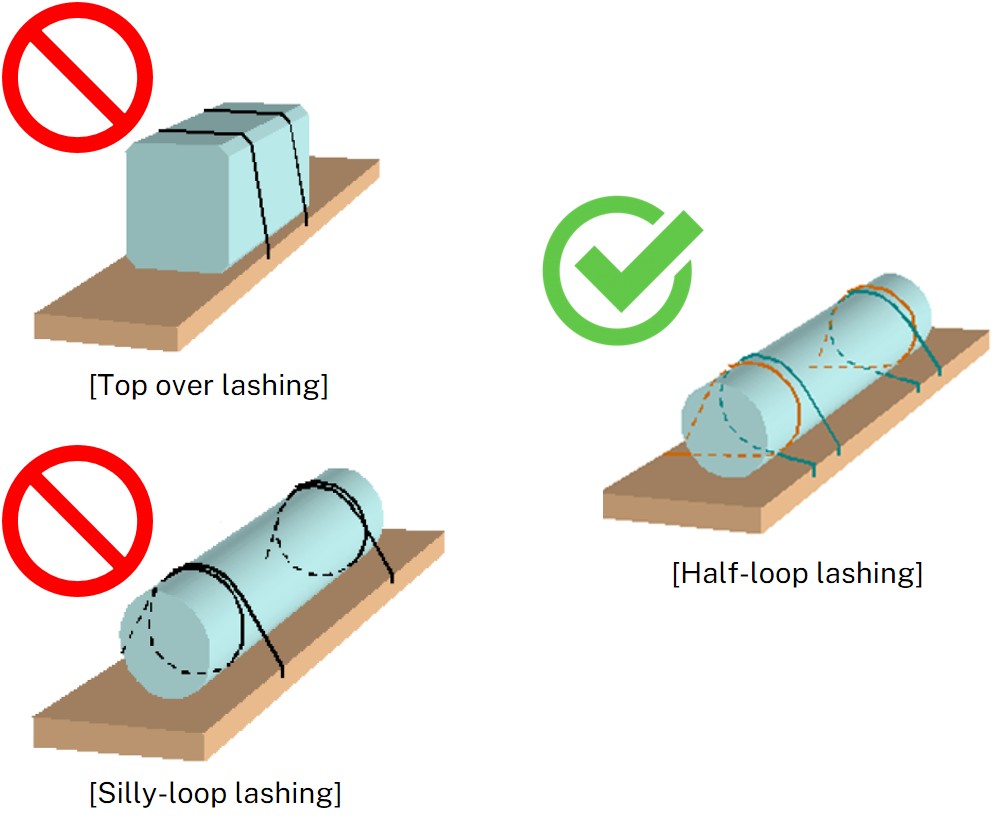

③ Half-Loop Lashing

- Loop lashing is a securing method used to prevent transverse movement and overturning of cargo.

- Loop lashings must always be applied in pairs. One lashing shall start and finish on the same side of the cargo, while the corresponding lashing shall start and finish on the opposite side.

- This half-loop lashing configuration acts by “constricting” the cargo, effectively restraining rolling and rotational movements.

- By contrast, top-over lashing or silly-loop lashing may be ineffective on curved surfaces, as belts or wires may slip under vertical loads. Vessel vibration and rolling can also cause continuous lashing displacement.

④ Direct Lashing

- Where the cargo has a high center of gravity (COG), loop lashing alone may be insufficient to prevent overturning. In such cases, direct lashings shall be applied as upper restraints.

- Direct lashings shall be arranged with a lashing angle of approximately 30–60 degrees from the horizontal, applied symmetrically on both sides to further enhance overturning stability.