When handling oversized or heavy cargo in container transportation, practitioners frequently encounter the terms OOG (Out-of-Gauge) and Break Bulk cargo.

However, depending on terminal conditions, carrier policies, container specifications, and vessel structure, the same cargo may be classified as OOG in one case and as Break Bulk in another. This often leads to uncertainty regarding the exact criteria used to distinguish between the two.

This article is intended to provide shipping professionals with a practical, operations-based explanation of the criteria used to differentiate OOG and Break Bulk cargo, to support cargo review, freight quotation, and customer communication.

1. Basic Concepts: Bulk vs. Break Bulk

Before examining OOG and Break Bulk in detail, it is useful to clarify the fundamental concepts of Bulk and Break Bulk as used in the shipping industry.

These terms are often used interchangeably in practice due to their similar wording. However, in this article:

- OOG / Break Bulk refers to transport methods for special cargo on container vessels, while

- Bulk / Break Bulk refers to general classifications based on cargo form.

Understanding this distinction will help clarify the discussion that follows.

① Bulk Cargo

Bulk cargo refers to cargo handled without packaging, loaded in loose form.

- Loaded directly into the vessel’s cargo holds without packaging

- Typical commodities include:

- Grains (corn, wheat, etc.)

- Minerals (coal, iron ore, etc.)

- Crude oil, gas, and similar commodities

- Commonly transported by bulk carriers or tankers

② Break Bulk Cargo

Break bulk cargo consists of cargo handled as individual units, suitable for lifting and securing.

- Packaged cargo: Wooden boxes, crates, skids, etc.

- Unpackaged cargo: Excavators, steel coils, steel products, large machinery, and structures

- Loading method: Cargo is lifted individually by crane and loaded one unit at a time

In summary:

① Bulk cargo is cargo “poured or loaded in loose form,” while

② Break bulk cargo is cargo “handled as individual units.”

2. Classification in Container Shipping: OOG vs. Break Bulk

When classifying special cargo in container shipping, the most important practical question is:

“Can the cargo be stuffed and shipped using a single flat rack container?”

The answer to this question provides the most practical basis for distinguishing between OOG and Break Bulk cargo.

① OOG (Out-of-Gauge) Cargo

OOG cargo refers to cargo that exceeds the standard loading limits of a dry container but can still be stuffed into a single flat rack or open top container and shipped on a container vessel.

Typical characteristics include:

- Cargo dimensions (length, width, height) exceeding standard dry container limits

- Cargo weight exceeding the maximum payload of a standard dry container, or creating concentrated loads

② Break Bulk Cargo (Container Vessel Basis)

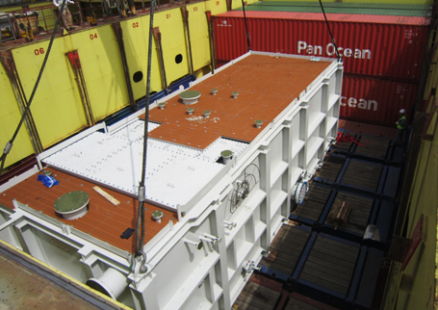

Break bulk cargo refers to cargo that cannot be stuffed and shipped using a single flat rack container due to excessive size or weight.

On container vessels, break bulk cargo is typically handled by:

- Arranging multiple flat rack containers side by side to form a bed, and Lifting and loading the cargo separately onto the prepared base

- Because container vessels can handle both standardized containers and break bulk cargo, this method can be an effective alternative when cargo volume is limited or when bulk carrier schedules are unavailable.

3. Factors Considered by Carriers When Deciding Between OOG and Break Bulk

While shippers typically provide cargo size and weight information, carriers consider additional operational factors when determining the handling method:

- Specifications of the container to be used for stuffing (size, maximum payload, etc.)

- Inland transportation method and restrictions from origin to terminal (and similarly at destination)

- Structural characteristics of the intended container vessel

- Handling capabilities of the loading and discharge terminals

- Expected weather conditions during the shipment period (typhoons, low-pressure systems, etc.)

In other words, cargo classification is not determined solely by cargo characteristics.

Instead, carriers evaluate the above factors and then decide on the handling method, which in turn determines whether the cargo is classified as OOG or Break Bulk.

This is why the same cargo may be handled as OOG at Busan Port, but as Break Bulk at a specific port in Japan.

4. Cargo Information Checklist

When discussing OOG or Break Bulk feasibility with carriers or forwarders, providing the following information in advance can significantly improve review speed and accuracy:

- Cargo dimensions (Length × Width × Height, mm)

- Cargo weight (including confirmation of packing weight)

- Packing type (Wooden box / Crate / Skid / Bare, etc.)

- Center of gravity information

- Lifting points and lashing points

- Availability of drawings or photographs

- Port of Loading (POL) / Port of Discharge (POD)

- Cargo origin and final destination

- Preferred shipping period and schedule flexibility

- Gate-in / gate-out methods at loading and discharge terminals (truck, barge, etc.)

Having this information prepared in advance can significantly reduce repeated review cycles caused by additional drawing requests and re-evaluations.

5. Summary Comparison

| Category | OOG Cargo | Break Bulk Cargo (Container Ship) |

|---|---|---|

| Unit of shipment | One special container (Flat Rack / Open Top) | Cargo loaded on multiple flat racks |

| Operational nature | Container-based special cargo | Comparable to conventional break bulk operations |

| Approval process | Relatively standardized OOG approval | Individual coordination and approval with carriers and terminals |

| Schedule risk | Relatively low | Relatively high |

| Cost structure | More predictable | Case-by-case, high variability |

| Applicable cargo | Oversized/heavy cargo that fits on one container | Ultra-large, ultra-heavy, or irregularly shaped cargo |